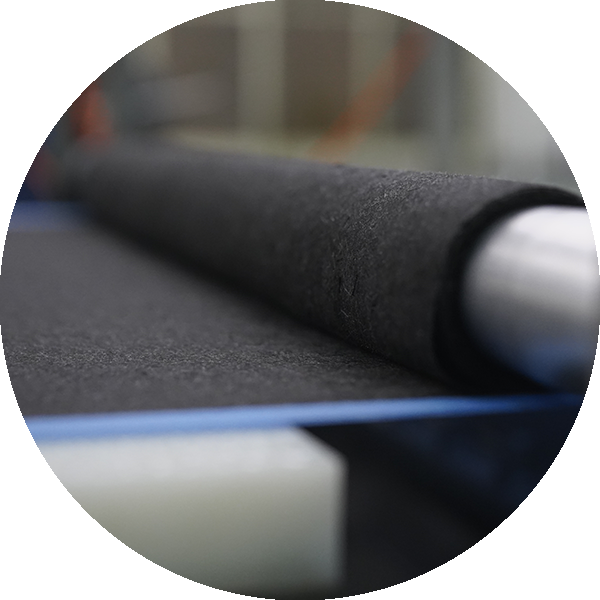

Development and production

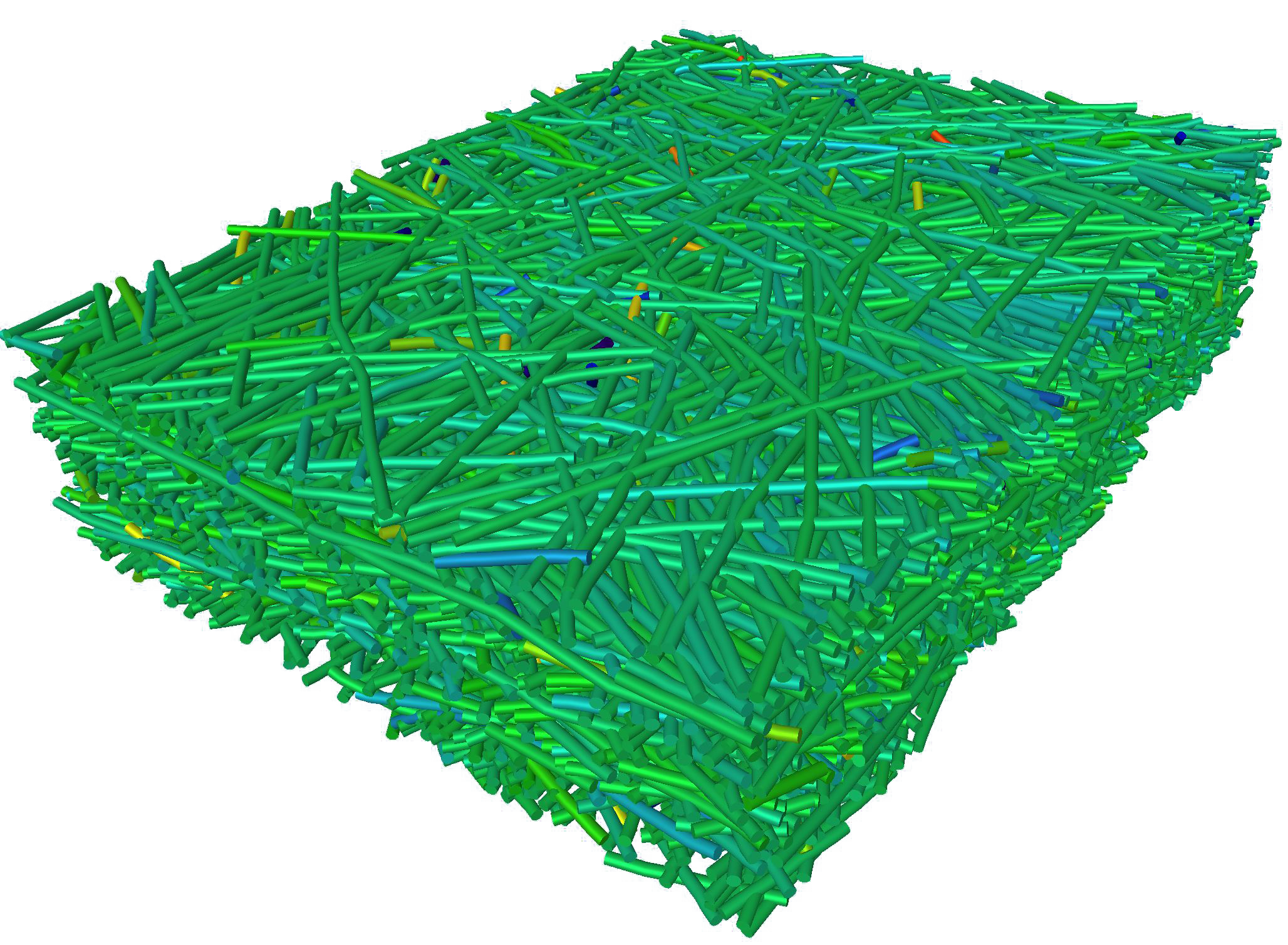

Our specialty is the processing of high-performance fibers, especially carbon, graphite, ceramic and metal fibers. We also place a special focus on the development of applications based on residual and recycled materials.

The rapid retooling and expandability of the modular machine and plant park guarantees us extremely flexible production. Of course, we work according to the highest safety and quality standards.

nonwoven (wet-laid) equipment in laboratory, pilot and production scale, form the core of our instrumentation. Diverse inline finishing and modification options for adjusting surface, porosity and functionality create additional added value. Diverse in-house analytical capabilities and close cooperation with reliable external partners accelerate every development phase.

Selection of materials

Pre-development

Evaluation

Production

Experience is our specialty

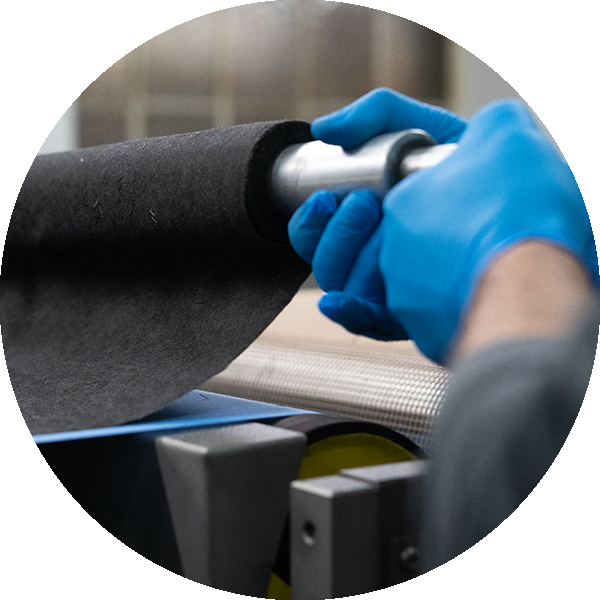

Often there is a lack of the exact right product to complete a project. Our many years of expertise in specialty nonwovens guarantees you a high-end product to your specifications.

Scalable according to your needs

NonWoven365 specializes in developing and producing specialty nonwovens for niche applications. The fast retooling and expandability of the modular machine and plant park guarantees us extremely flexible production in accordance to the highest safety and quality standards.

Fine adjustable down to the last fiber

nonwoven- (wet-laid) systems in laboratory, pilot and production scale, form the core of our instrumentation. Diverse inline finishing and modification options for adjusting surface, porosity and functionality create additional added value. Diverse in-house analytical capabilities and close cooperation with reliable external partners accelerate every development phase.

Technology & Innovation

In order to design materials with the highest performance, you need to fully understand the structure-effect relationships behind the technology. That’s why we partner with the leading global technology groups and academics to connect nonwoven expertise with applications know-how.

Therefore, being able to determine each fiber of the nonwoven to its exact location and being able to translate the optimal structure into a manufacturing process is our USP.

By modern simulations techniques, the interaction of the nonwoven with its environment can be predicted and influenced. Be it electrolyte flow in Redox-Flow-Batteries, electrical conductivity for the gas- and water exchange in fuel cells and electrolyzers.